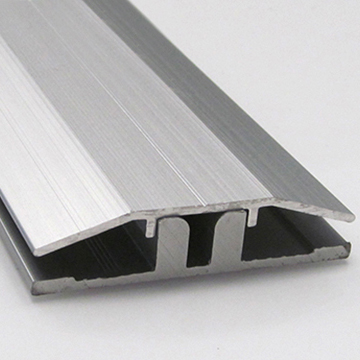

Mill finish is the natural finish that aluminum profiles have as they emerge from the extruder die.It’s basically bare aluminum. The appearance is natural color of aluminum and it is sliver, as without any surface treatment, there will be some die lines and marks on the surface and it is widely used in the inner decoration and inner parts of finished products. Mill finish will oxidize with a light white powder (aluminum oxide) as it is exposed to air and moisture. Mill finish profiles are used mostly as inner parts of machines which are not in contact with humid air. Also, these profiles are suitable when the user does not carry decorative purpose.